Category: Development

Development redirecting to inverter with CUMon

Not a Complete Waste !

Get your free energy diverter

Energy Diversion to a Battery

NRGDivert Non Intrusive energy diversion

CUMonitor as Canbus Controller

CUMonitor as a Zero Export technique

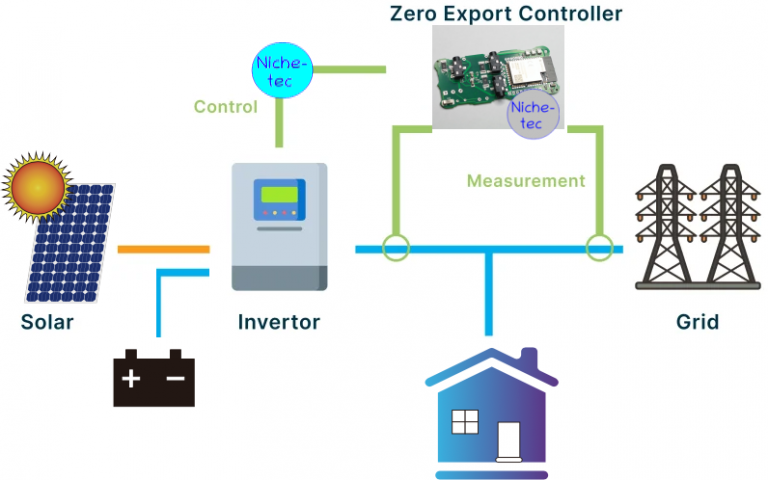

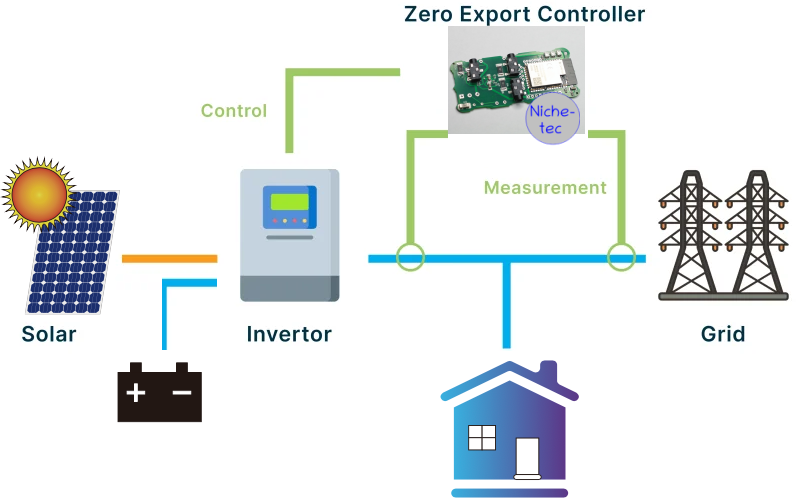

What does a Zero export Controller do and can we replace it with a CUMon ?

A zero export controller balances the energy from the Inverter and Battery with that consumed within the house. By ensuring that non of that energy is sent to the Grid. It proves that it has achieved this by measuring the current to the grid and finding it zero.

CUMon already uses the two current sensors to read PV current generated and the Exported Current. It then makes a prediction of whether the system is exporting to the Grid. To get it to function as a Zero export controller it needs to exert control over the inverter.

This should be possible using control on the RS485 or CAN bus. Most modern inverters have the export monitoring and control as an option built in.

CUMon offers the advantage that there is no rewiring of Mains Power and it is attached purely by using current clamps of existing cables

To get control of the inverter would require connecting to the CAN bus inputs and acting as a grid export current sensor.

This is definitely worth considering as there is no mains voltage involved it should prove a safe option for energy divertion